With so many changes and challenges in the food supply chain, what can growers and food manufacturers do to keep their crops and foods safe and healthy for consumers?

Keeping enclosed spaces free of contamination is critical for indoor growing environments and food manufacturing plants. According to the Food and Agriculture Organization (FAO), mycotoxin, or mold, affects up to approximately 25% of the world’s crops. Mold is a persistent challenge when growing indoors in greenhouses and vertical farms. For food manufacturers, bacteria such as E. coli, listeria, and salmonella can contaminate their facilities and products and lead to harmful outcomes. According to the CDC, every year an estimated 1 in 6 Americans, or 48 million people, get sick, 128,000 are hospitalized, and 3,000 die from foodborne diseases1. When food contamination triggers a recall, the direct costs can reach $10 million2, not including indirect costs. On the whole, USDA 2018 data shows that the impact of the top 15 foodborne illnesses was over $17 Billion3.

The current pandemic is driving the search for solutions to make workplaces and environments safer for employees. However, cleaning with chemicals or processes such as irradiation have detrimental effects on crops, food, and people. This is why AgriFORCE RCS is working with indoor growers and food manufacturers to implement a proprietary, safe and effective solution: hydroxyl generators.

What is the AgriFORCE RCS solution? How does it work?

AgriFORCE recently announced a worldwide licensing agreement with Radical Clean Solutions Ltd. (RCS) to commercialize their new proprietary hydroxyl generating devices within the controlled environment agriculture (CEA) and food manufacturing industries. The patent-pending system seeks out and destroys both airborne and surface-based mold, bacteria, virus, odorous and volatile organic compounds (VOCs), as well as other pathogens and pollutants in real-time.

Roger Slotkin, CEO of Radical Cleaning Solutions Ltd., explains, “Our hydroxyl technology is dispersed throughout the environment in which it operates, thereby sanitizing all surfaces, materials, equipment and the air itself. It does so through a natural, chemical-free process that is 100% harmless to people, pets and plants.”

Indoors we are cut-off from the natural elements and processes that naturally clean the air by killing germs and viruses and removing pollutants. Pathogens enter facilities in a number of ways, including the people working inside them. Closed loop heating and ventilation (HVAC) systems for air conditioning increase the spread of pathogens, which can remain airborne for hours, or in some cases days. It is even more challenging in greenhouses and food processing plants, as these facilities are warm and humid and can create a breeding ground for contaminants. There can also be elevated concentrations of Volatile Organic Compounds (VOC) in indoor spaces.

Through the implementation of hydroxyl generators that kill pathogens and neutralize VOCs, AgriFORCE can help companies not only improve their bottom line but also better protect the safety of their employees and consumers.

What exactly are hydroxyls, and how do they help with air and surface sanitation?

Hydroxyls (° OH or HO °) are the unique atmospheric Hydroxyl Radical. HO are created in the troposphere (the air we breathe) by the reaction of ultraviolet light with H2O and O3 (ozone).

While hydroxyls are short-lived (<1 sec), they are highly active chemical species that participate as intermediates in reactions. They can break apart almost any molecule from water vapor to VOCs and everything in between. They are nature’s proven and healthy way to decontaminate air and surfaces. What atmospheric hydroxyls can do is remarkable, and at AgriFORCE we are looking to bring the power of nature inside.

Hydroxyls are the only solution that eliminates Viruses, Bacteria, Mold and VOCs virtually everywhere

Safely Removes all Mold and Pathogens

- RCS reports 99.999% of tested pathogens neutralized, backed by over 20 years of third-party validated laboratory and field testing

- Bacteria, viruses and mold are neutralized by the action of hydroxyls (and UV light)

- Hydroxyls are natural and all around us and are safe to humans, animals and plants

Neutralizes Volatile Organic Compounds (VOCs)

- Hydroxyls ultimately decompose them into harmless small natural (gaseous) molecules such as CO2, H2, N2, O2, or HsO

- Neutralize toxic inorganic gasses

Originally discovered by NASA

- Over 50 years ago, NASA confirmed that it was the action of the pathogens hydroxyl and not ozone that was responsible for neutralizing pathogens and Volatile Organic Compounds.

- AgriFORCE RCS offers an improved, patent-pending, practical, cost effective and reliable system to replicate this process

FDA considers Hydroxyls Safe

- FDA has reviewed a wide range of air purification devices and concluded that atmospheric hydroxyl generation devices are considered safe based on prevalence in nature.

No Science or Research indicates Harmfulness

- “No hard science or research indicating that hydroxyl radical generation is harmful to humans. That applies to both atmospheric and man-made generation.” Source: NIEHS Office Of Communications and Public Liaison – Colleen Chandler, 2010

What are some of the areas the AgriFORCE RCS solution can work in? How is it different from other filters/systems currently available?

The AgriFORCE RCS Engineered Solutions work in Greenhouses, Manufacturing Plants, Offices and Food Storage, and can be deployed in transportation along the supply chain. Between SOPs and conventional cleaning and sterilization agents there is only so much protection that can be afforded. We offer a customized system for facilities to meet the form, fit and function necessary for the manufacturing space – from built-in units that fit your air handling systems to stand-alone units wherever needed.

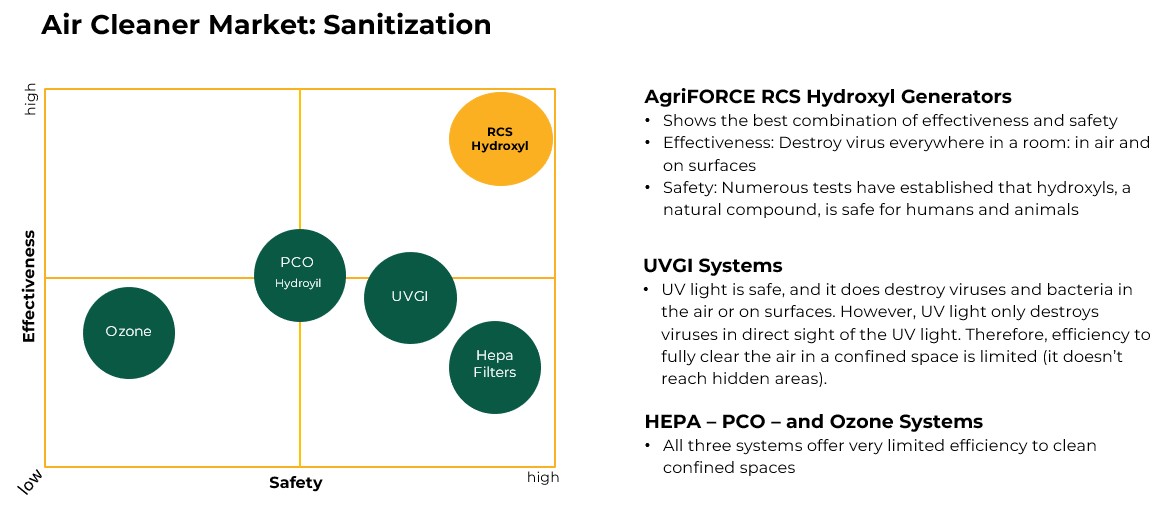

RCS reports that compared to other solutions such as UVGI, Hepa, PCO and Oxone systems, RCS Hydroxyl Generators show the best combination of effectiveness and safety:

For UVGI Systems, the UV light is safe and effective on viruses and bacteria in the air or on surfaces, however only in the places that are directly exposed to the UV light – it isn’t able to reach hidden areas and may not be highly effective for moving air.

For systems that are dependent on filters, such as HEPA systems, the challenge is that bacteria, mold, pollens and other pollutants get trapped in the filters, but not killed. If the filter is not changed, contaminants start to grow and cause the indoor air to smell. Also, these units do not remove VOCs and some may emit unhealthy fumes.

AgriFORCE RCS systems effectively clean the air and surfaces throughout the entire space, and are more cost effective as they do not contain filters that require replacement. They are safe with no use of chemicals, fumes or off-gasses.

Want to learn more about AgriFORCE RCS Solutions for controlled environment agriculture and food manufacturing?

Contact us at rcs@agriforcegs.com to book a meeting today and discuss how to deploy an engineered solution for your business needs.

- Center for Disease Control and Prevention, Fast Facts About Food Poisoning https://www.cdc.gov/foodsafety/food-poisoning.html

- “Recall: The Food Industry’s Biggest Threat to Profitability”, Food Safety Magazine, October 11, 2012. https://www.food-safety.com/articles/2542-recall-the-food-industrys-biggest-threat-to-profitability

- U.S. Department of Agriculture Economic Research Service, “Costs of major foodborne illnesses in the United States increased to $17.6 billion in 2018”

https://www.ers.usda.gov/data-products/chart-gallery/gallery/chart-detail/?chartId=101488